OUR SERVICES

Designing & Planning

Design Facilities

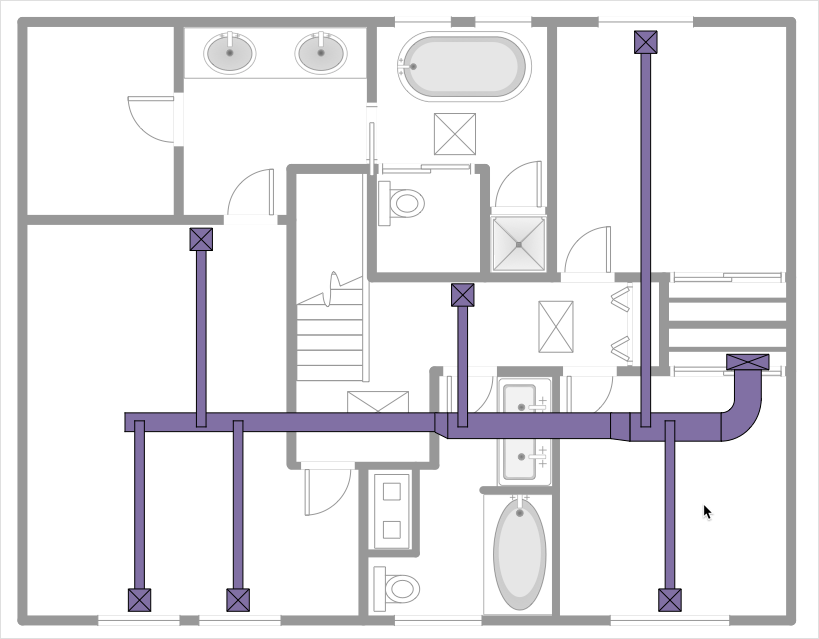

All the design facilities are available in house. The hardware consist of bank of computers, utilizing to the latest in electronic software enabling us to provide prompt efficient, highly engineered system. This is to enable the client to have the lowest possible operating cost at the lowest possible installation Cost. The design group is headed by the experienced professionals.

Planning Facilities

The company lays special emphasis on project management, planning. The project planning Department uses the modern tools to do detail analysis of the dynamics of the project using the concept of PERT, CPM, OPERATIONS SCHEDULING, CRITICAL PATH SCHEDULING etc.

Execution

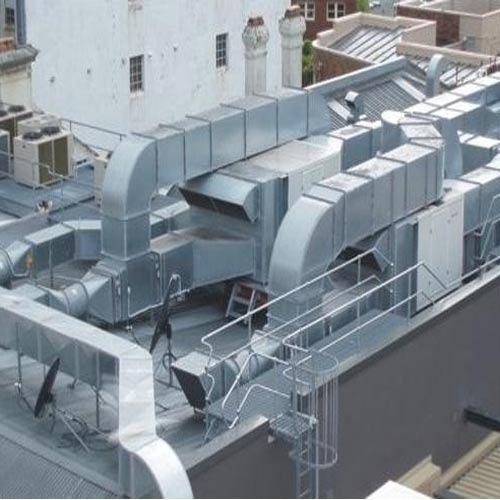

Luft Care Services maintains a team of experienced engineers who are conversant with AutoCad drawings of HVAC fields. Our engineers are also trained in latest planning-cum-scheduling software, besides having modern Auto CAD Stations.

We have a team of Highly Trained and Experienced Installation and Service Technicians. We are able to effectively manage our craftsmen, ensure superior quality control, meet the most rigorous time schedules, and comply with all safety measures.

1. Chillers

a. Air cooled

b. water cooled

2. VRF System

3. DX Type Unit

4. Package Type Unit

5. FCU

6. Cassette Type AC

a. 4 Way Cassette

b. 2 Way Cassette

c. 1 Way Cassette

7. HI-Wall Type Split Unit

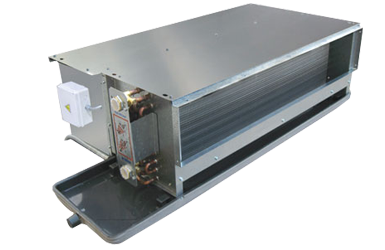

8. Ductable Unit

9. Tower AC

10. Ceiling suspended AC

11. Floor mounted AC

12. AHU

a. Ceiling mounted

b. Floor mounted

13. HRW

14. Lossnay Unit

15. Air Washer/Scrubber

16. Cooling Tower

a. Open type

b. Close type

17. Pumps

18. Hot water generator

19. Ventilation Fans

a. Axial Fan

b. Inline Fan

c. Jet Fan

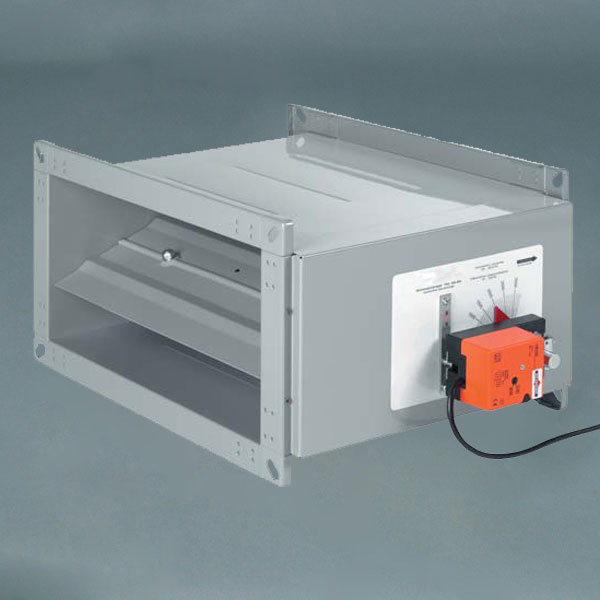

20. VAV

21. CAV

22. VFL

23. Butterfly Damper

24. Fire Damper

25. Collar Damper

26. VCD

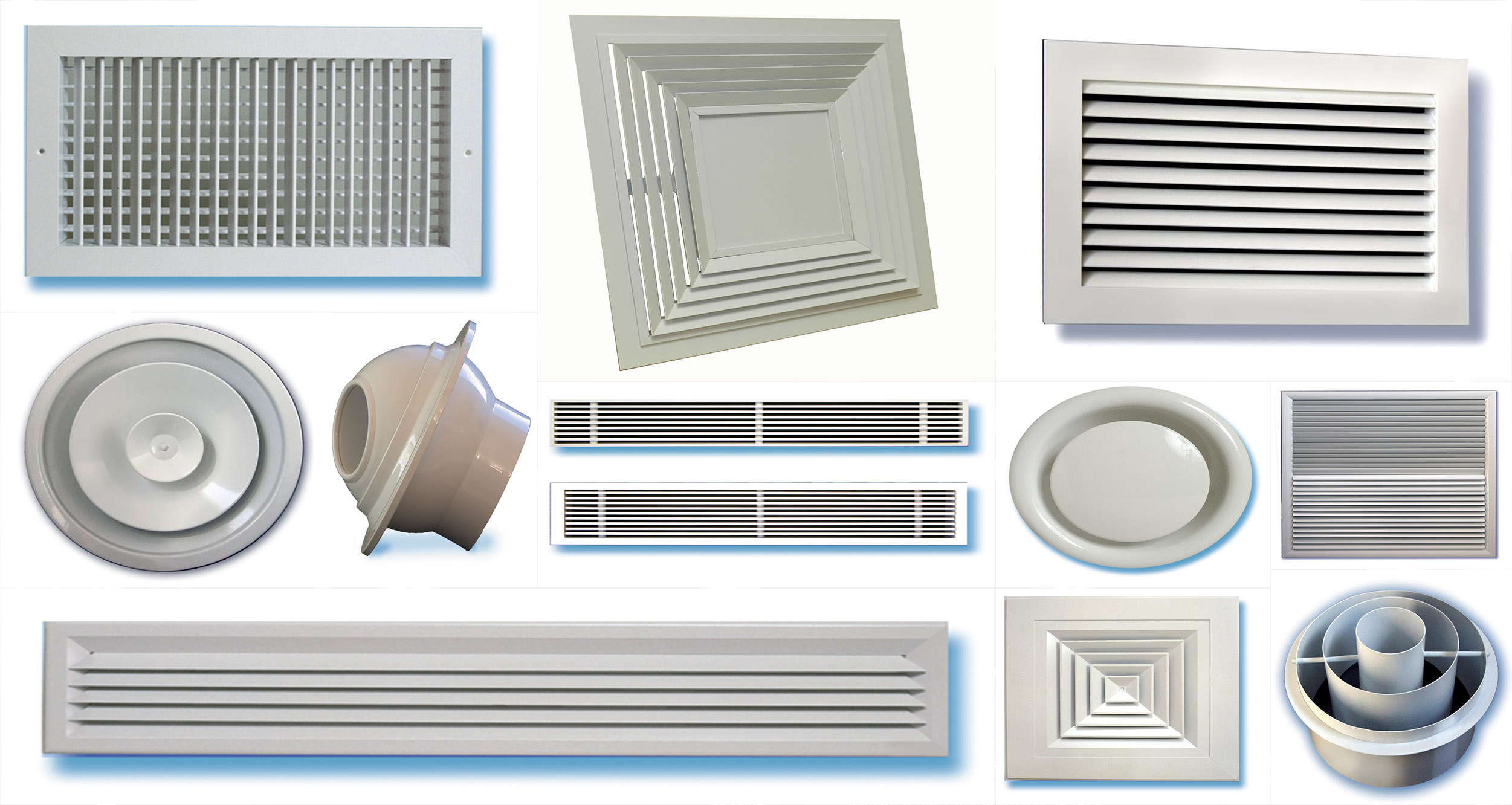

27. Grill & Diffuser

28. Air & Dirt Separator

29. Vacuum Degasser

30. Expansion tank

31. Ducting System

32. Piping system

33. Remotes System

a. Corded

b. Cordless

c. CRC

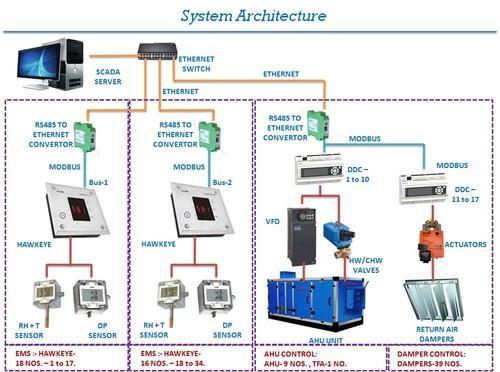

34. BMS Systems

Testing & Commissioning

- Air and Water Balancing

- Functional Performance Testing

- Control System Verification

- HVAC Commissioning

- Sound and Vibration

- Fumehood Testing

- Duct Leakage Testing

- Indoor Environmental Testing

- Cooling Tower Performance

- Pre-Construction Plan Review

After Sales Service

We provide after sales service and preventive maintenance to the products installed by us during the warranty period. The Warranty Period may vary as per the OEM Standards.

AMC

All air-conditioning systems like any other machine, depreciate with time. And If not properly maintained, they progressively lose efficiency, consume more power, and drain profits. Inadequate monitoring and maintenance of your air-conditioning system can cause a lot of inconvenience. This is why we, at Luft Care Services do comprehensive Annual Maintenance Services (AMC) that will ensure smooth functioning of your products.

To effect a seamless operation and service for client we follow what is called “PPM: Planned Preventative Maintenance”.

Planned Preventative Maintenance (PPM)

PPM is a schedule of planned maintenance operations aimed at the prevention of breakdowns and failures. PPM ensures continuity of service, maximises efficiency and reduces total running costs.

Luft Care Services provides comprehensive Planned Preventative Maintenance (PPM), a schedule of logged, planned maintenance operations adhering to the guidelines and to the specifications of equiment designed by the manufacturer.

Our PPM programs are designed to preserve and enhance equipment reliability by replacing worn components before they actually fail, which includes: equipment checks, partial or complete overhauls at specified periods, oil changes, filter changes, seal replacements, lubrication, etc.

“Planned Preventative Maintenance greatly reduces call out costs and labour fees, causes less disruption and is a much better alternative to risking a potentially damaging breakdown of equipment.”

PPM Overview

- PPM Planning - A schedule of maintenance is tailored specifically to the equipment and assets on site in accordance with manufacturer specifications.

- Site Inspections - Planned site visits by engineers to audit and assess equipment, determine reliability, efficiency and record equipment deterioration and status.

- Audit & Assess - Our auditing services and diagnostics are designed to predict possible equipment failure and negate the likelihood of such through our program of planned maintenance.

Copyrights © 2018 Luft Care All Rights Reserved | Designed & Developed By cwp digital